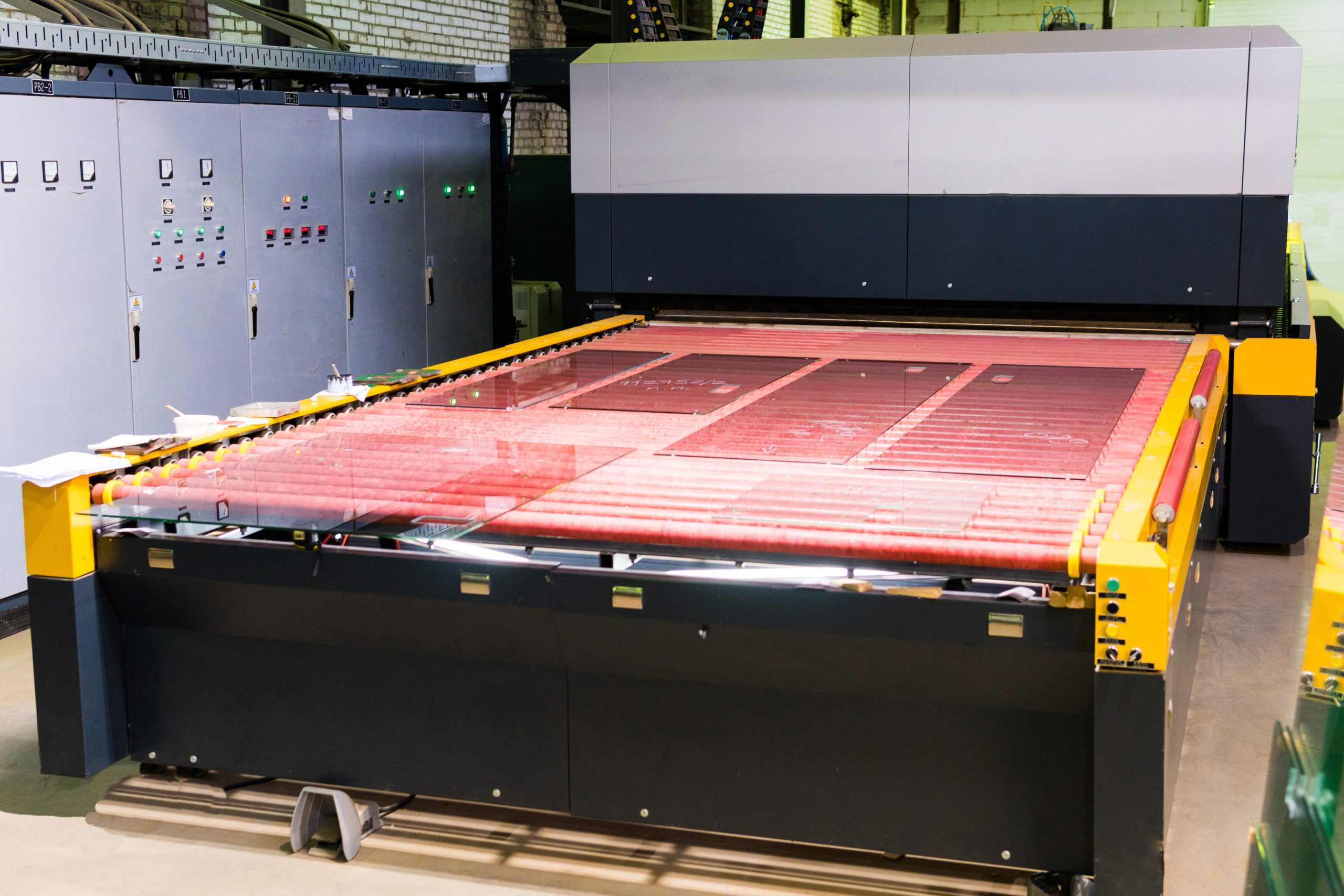

Industrial belts provide synchronized motion control essential for precision glass processing operations. In glass cutting systems, they ensure accurate blade positioning for clean cuts with minimal material waste. During edging and polishing processes, timing belts maintain consistent glass panel movement to achieve uniform surface finishes. Conveyor systems utilizing timing belts transport glass sheets safely between processing stations while preventing slippage and damage. For printing and coating applications, these belts enable precise glass positioning to ensure accurate pattern registration and even coating distribution.

We provide specialized timing belt solutions designed specifically for glass processing applications. Our product range includes high-precision belts that maintain dimensional stability for critical cutting and machining operations. For glass handling applications, we offer belts with enhanced grip surfaces to prevent panel movement during transport. Low-noise versions are available for noise-sensitive production environments, while custom lengths ensure proper integration with existing equipment. Our maintenance programs help optimize belt performance and service life, reducing unexpected downtime in glass manufacturing operations.